In the vast expanse of the condiment market — which includes everything from barbecue and pasta sauces to Chinese flavorings,Chili sauce, mayonnaise, ketchup, mustard, as well as an array of dressings and vinegars — what drives one product to stand out from another are elements such as its inherent quality, a critical aspect for consumers, complemented by its packaging, quantity, and the preservation of the integrity of the sauce pieces.

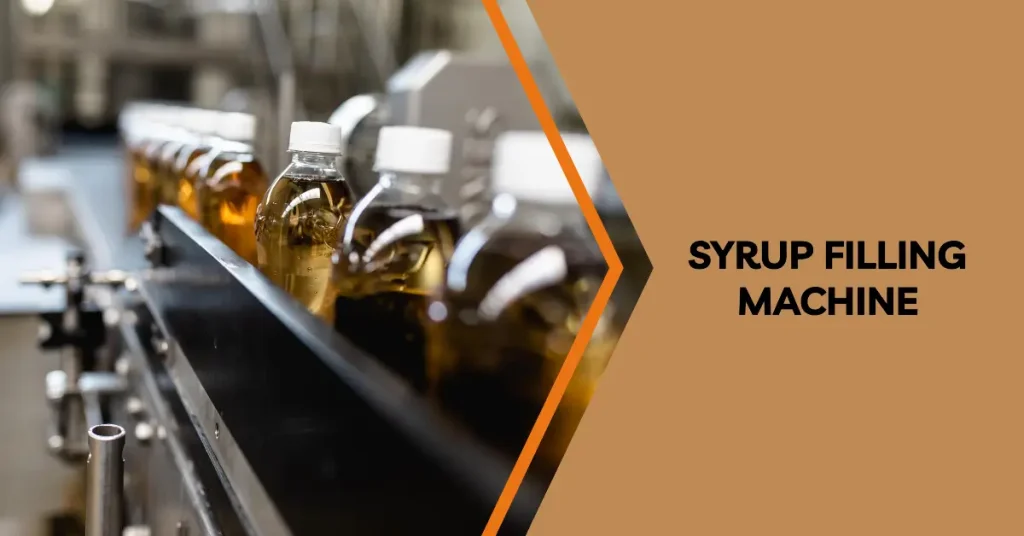

No matter which types of sauce filling machines,piston or pumps dosing technology, Npack presents multiple options to fulfill your quality expectations, such as a bottom-fill feature and anti-drip systems, along with various levels of sanitization processes, which include sloped draining troughs, CIP cleaning stations, COP foam stations, and cap decontamination measures.

- Enhanced Precision in Filling ,an innovative servo mechanism provides meticulous control over fill volumes, achieved through uniform piston movements. This adjustable system is crafted with precision in mind.

- Cutting-Edge Servo Drive Technology,a sophisticated servo drive underpins our volumetric filling system or lobe pump, ensuring consistency and exactitude in the filling process. Energy consumption is minimized while the mechanical burden is lessened due to the piston’s optimized vertical dynamics.

- Simplified Adjustment Without Tools,altering the PLC settings is straightforward and does not necessitate specialized equipment, potentially enhancing operational efficiency. The system’s refined servo controls offer precise dispensing across various bottle sizes and viscosities with ease.

- Versatile and Wide-Ranging Applications,the automated servo-driven sauce filler is crafted for flexibility, suitable for deployment in diverse sectors, including gastronomy, health sciences, chemical production, beauty products, and more.

- Food grade construction material,For sauces and dressings, our filling systems exceed the hygiene benchmarks set by industry standards. We craft these systems with materials known for their sanitary qualities,

- Easy cleaning design,eaturing tri-clover connections and designs that prioritize ease of cleaning,CIP system can working well with our sauce filling machine

When it comes to the filling of sauces or dressings, Npack’s expertise becomes indispensable. We’re positioned to help you carve out a distinctive presence with our diverse range of filling techniques designed specifically for the sauces and dressings sector. Whether it’s volumetric, by weight, or mass flow metering technologies, options for filling at hot or ambient temperatures, or different cap types — screwed on or inserted — we guarantee a pristine filling process, compliance with hygiene regulations, and total flexibility through rapid tooling changeovers.Here are video for your referene,for more please follow our YouTube or contact us.

You May Like

Find more solutions on our post

Shanghai Npack to Showcase Advanced Liquid Filling, Capping, and Labeling Machines at Warsaw Pack 2025

Discover how Shanghai Npack’s liquid filling machines, capping machines, and labeling solutions at Warsaw Pack 2025 can revolutionize your packaging process….

A Unique Guide About Cosmetic Filling Machine

The development of Cosmetic Filling Cosmetics play a significant role in the female consumer market….

A Unique Guide About Automatic Labeling Machine

An automatic labeling machine automatically complete material sorting, conveying position, label application, material delivery and…

A Unique Guide about Automatic Screw Capping Machine

An automatic screw capping machine is generally contained in the second stage of the liquid…

You Need to Know about Detergent and Detergent Filling

About detergent In this era when every household has a washing machine, detergents have become…

You need to know about Bottle Filling Solutions

Foreword There are various packaging for daily necessities we use in our daily lives. The…