Monoblock bottle filling and capping machine for cosmetics Liquid

This monoblock bottle filling and capping machine is specifically designed for the cosmetics industry, it is perfect for filling various semi-creams and liquid materials, including BB cream, serum, foundation, body cream, isolation cream, and skin cream and lotion.

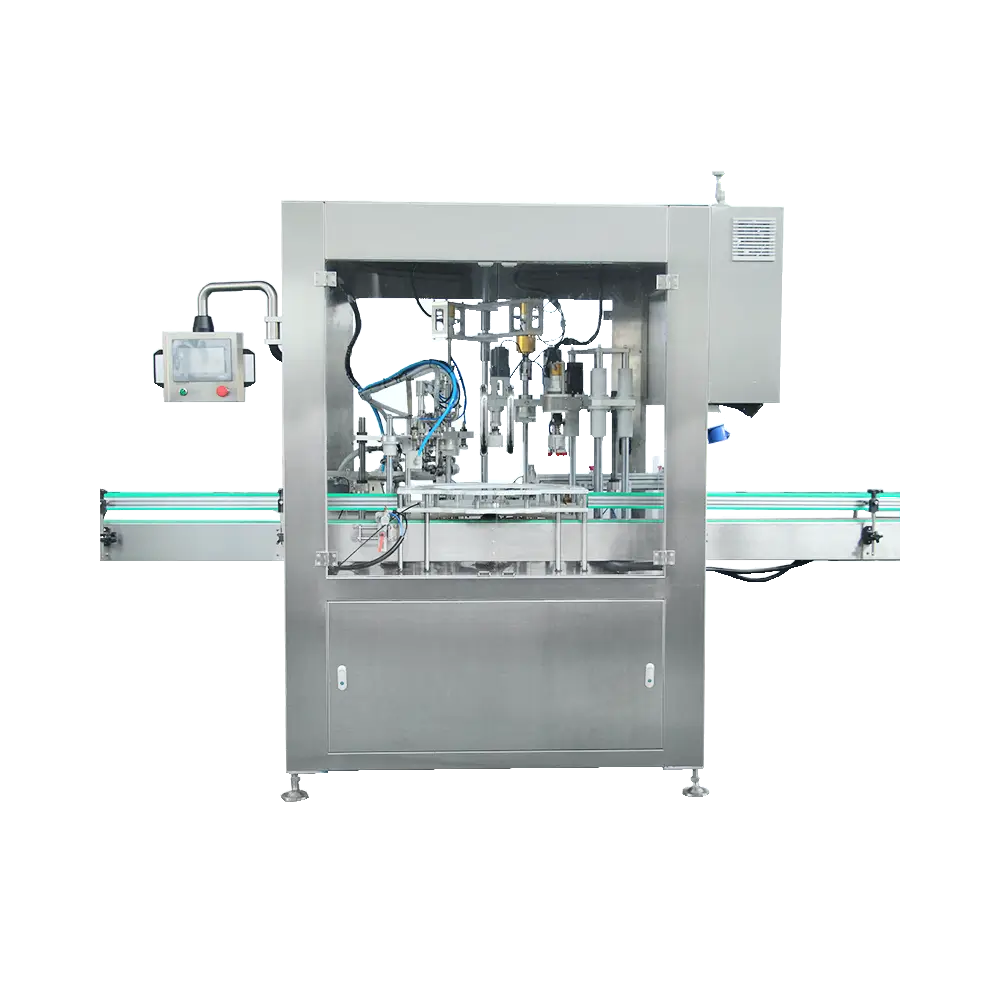

The machine is designed to meet GMP standards , the electric standard can be made accroding to customers countries, such as canada, and australia standard. This machine can be customized to handle bottle loading automatically, automatic filling, stoppering, capping, and finished products discharging, with all actions and movement simultaneously.

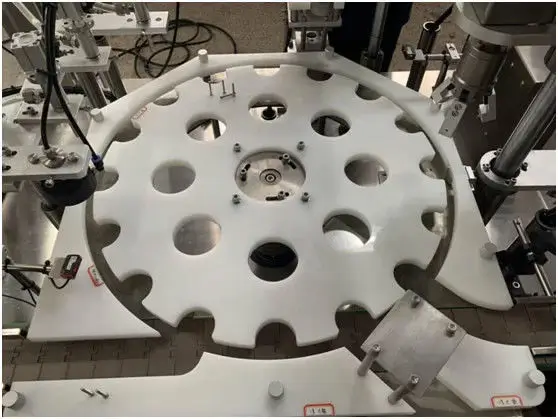

The machine fully reflects the advanced, reliable and reasonable design ideas required by GMP for pharmaceutical equipment, focuses on people-oriented, and reduces human factors in the use of equipment. According to the characteristics of customer products, it is customized as manual bottle loading, automatic filling, automatic ball bearing base, automatic ball bearing, swing arm capping, pre-rotation, servo capping, and automatic bottle discharging.

- The filling process of the machine uses 316L stainless steel and sanitary hoses.

- The machine uses a reliable high-precision piston pump for filling, and the filling volume and speed are easy to adjust.

- The filling components are easy to disassemble, easy to clean, disinfect and sterilize

- The machine adopts lifting filling, and the injection nozzle can be extended into the bottle to ensure effective filling

- The pre-spin mechanism invented by our company is adopted to greatly improve the success rate and efficiency of capping

- The servo motor is used for capping, and the capping speed and torque are directly adjusted in the human-machine interface for greater convenience

- PLC fully automatic control, the whole machine is made of stainless steel, and the high-definition visible organic glass frame

- It has fault alarm, door opening, and mechanical overload automatic shutdown devices

- Tool-Free Changeover: No tools required to switch between different size bottles, making it highly efficient for various production needs.

- When filling, a high-precision piston pump is used for filling according to the test product

- It has a precise control function of no filling without bottle

- The capping lifting mechanism is controlled by cam, and the structure is stable. The transmission mechanism uses an eccentric cam transmission, which has low noise and long service life. The outer cover hopper adopts a single track to feed the cover.

| Item No. | NP-MFC Series |

| Applied Bottles | Customized |

| Output Capacity | 30-40bpm |

| Filling Accuracy | ≤±1%(30ml) |

| Filling range | 5ml to 120ml |

| Filling heads | 1 to 4 nozzles |

| Capping heads | 1 to 2 heads |

| Voltage | 220V/50Hz (Customized Optional) |

| Auto-capping Rate | ≥99.9% |

| Auto-Stopper Rate | ≥99.9% |

| Air consumption | 1.3 m3/h 0.4-0.8Mpa |

| Power | 2.5KW |

| Weight | 700KG |

| Size | Refer to layout |

Related Products