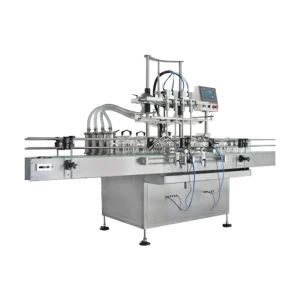

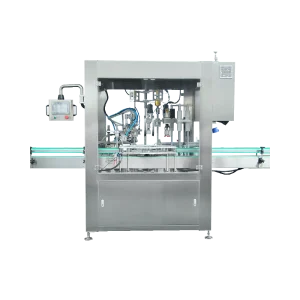

NP-VF Automatic Piston Filling Machine

The NP-VF Inline piston filling machine was driven by a main servo motor or each piston driven by individual servo motor.It is npack main products, after 10 years development, it is capable for filling liquid with high viscosity and high foam in the food, chemical and cosmetics industry. For automatic volumetric measurement dosing system, the NP-VF is one of the best choice with stable working technology, high efficient and lower investment.

- Machine construction structure material is 304 stainless steel ,with material quality certificate

- Pistons and dosing head is made by 316L SS with material certificate

- Piston gaskets is made by non corrosive material according to the liquid products.

- Electrical installation and CPU is water proof designed and building.

- Pneumatic adapt with SMC or Festo as a main part.

- HMI is installed in the dosed product release side.

- Equip with minimum 3 emergency stop buttons, one near the touch screen, one near

empty product insertion side and one in the back side of the machine. - CPU and HMI is Europ, Japan and China Brand

- Electrical components schneider

- Identification of each cable with single line electrical diagram for the whole electric

installation. - Ball-bearing and seals are SKF and China top level brand.

- Servo driven diving filling heads while dosing liquid

- pneumatic shut off and anti drips filling nozzles

- Drips tray is a standard feature

The NP-VF is an excellent piston filling equipment designed for dosing viscous liquids across various industries. It proves highly effective in the daily chemicals and cosmetics fields for dosing products like body lotion, cosmetic creams, emulsions, gels, hand soap, serums, shampoo, and detergents. Additionally, it has gained popularity for filling food liquids and sauces, including tomato sauce, ketchup, honey, soy sauce, and edible oils. The versatility of NP-VF makes it a valuable asset for precise and efficient dosing in a wide range of applications.

| Name | Specification |

|---|---|

| Filling Nozzles | 2-20 Nozzles |

| Production Capacity | 10 to 150bpm |

| Power | 1.5KW to 3KW, 220/380VAC |

| Accuracy | ±3ML base on 1000ML |

| Driven | Servo Motor |

| Filling Volume | 100ml to 5000ml |

| HMI | German or China Brand |

- Each servo motor driven by each piston stroke movement individually

- HMI One touch automatic Adjust for different size of containers

- Mixing top hoppers

- Double jacket hopper with heating

- Pressure top tank

- Rotary valve for food sauce with granular solid

Related Liquid Filling Machines