Ionized Air Bottle Rinser

WATERLESS RINSING CONTAINER WITH IONIZED AIR

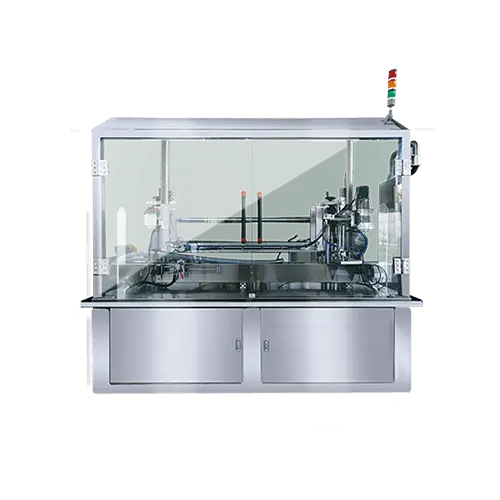

NP-IA Automatic Ionized Air Bottle Rinser

The NP-IA Automatic Ionized Air Bottle Rinser is an advanced solution for various bottles and containers. It is an indispensable asset in the beverage, food packaging and pharmaceutical industry because of the innovative design and advanced ionized air rinsing technology. This machine ensures that the interiors of glass jars, PET, and PP bottles are meticulously cleaned and disinfected before filling them with their respective contents.

With this suite of air bottle rinsing technology available—including inline, rotary, gripper, lowerator, and multi-station systems—you can tailor your cleaning approach to the specific needs of your line, whether running standard PET bottles, glass pharmaceutical containers, or uniquely shaped specialty jars.

We can make the bottle rinsing machine with below features such as variable speed drives for adjusting to changing production rates; Photo sensors and bottle detection for automation and waste reduction; Touchscreen controls for ease of use and customization; Vacuum extraction and diverter heads for enhanced cleanliness on specialty products

Robust Material:

The main components of our automatic high-speed bottle washing machine are constructed using 304/316 stainless steel material. Not only does this ensure a visually appealing appearance but also provides strong corrosion resistance, stable performance, and low maintenance costs over time.

User-Friendly Interface:

Equipped with intuitive interfaces that allow easy adjustment of settings, real-time monitoring of the cleaning process, and troubleshooting capabilities if needed; our ionized air bottle rinsers provide convenience for operators while maintaining optimal performance standards.

Technology:

The machine can effectively remove and neutralize particles adhering to the bottle’s surface. By utilizing ionized air rinser technology, our machine can efficiently clean dust, debris, and contaminants from bottle surfaces, thereby enhancing product quality and safety.

Washing Speed:

Our machine can wash bottles fast and thoroughly and is suited for continuously flowing bottles on high-speed packing production lines. It can handle abundant bottles in a short time while not affecting the cleanliness.

Low Consumption:

In comparison to traditional water-based flushing methods, the ion air flushing system significantly reduces water consumption. This manner promotes sustainability and reduces operational costs for businesses.

Range Applicability:

This machine can handle different bottle sizes and shapes while effectively cleaning and disinfecting various containers. Its versatility makes it an ideal solution for businesses with diverse packaging needs.

Integrated Production Line:

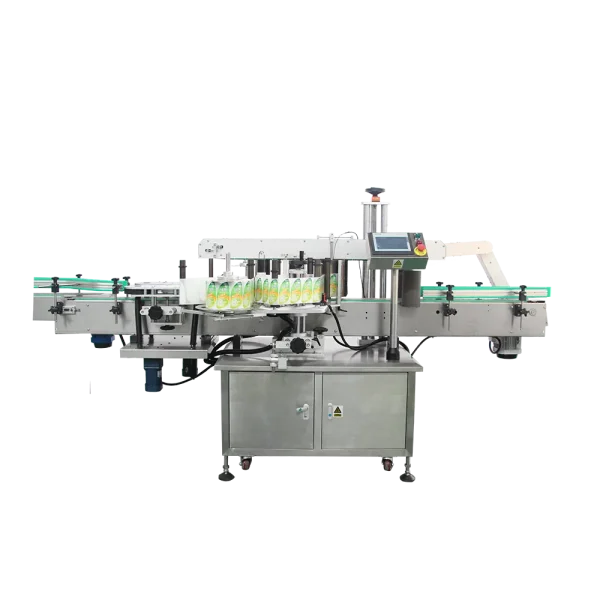

When paired with complementary equipment such as glass or plastic bottle filling machines, capping machines, and labeling machines, our ionized air bottle rinser seamlessly integrates into liquid production lines. This integration enhances overall production efficiency by streamlining the bottling process.

The Ionized Air Bottle Rinser, developed and produced by NPACK, is a cutting-edge solution to address the issue of bottles not being thoroughly cleaned. This innovative machine utilizes advanced technology to ensure that bottles, glassware, and various containers are impeccably rinsed, promoting enhanced hygiene standards. One of the key features of this system is its linear conveyor belt transmission design. By employing this mechanism, the Ionized Air Bottle Rinser optimizes efficiency and accuracy in the cleaning process.The machine is mostly application in the fields of phamarceuticals, cosmetics and food industry.

| Power | 220V 1Phase, 0.75KW |

| Applied Container | Plastic Bottles, Glass Bottles, Jars |

| Speed: | 20-60b/m |

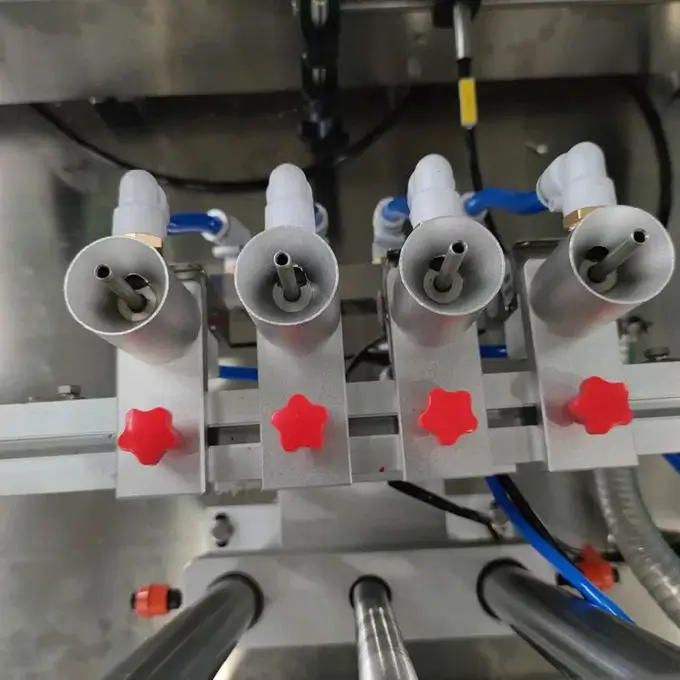

| Rinsing Heads | 4,6,8,10 12 and 16 heads |

| Air Pressure | 0.6MPA |

The automatic flip-bottom air bottle cleaning machine is a washing machine used for washing bottles before the bottle into a washing machine. It aims to guarantee the bottles are clean, removing any possible contaminants that could impact the quality of the liquid inside. Here is a basic explanation of how it operates:

- Utilizing a water-free solution to clean the interiors of containers, the machine can minimize environmental impact and maintain high sanitation standards.

- When it begins, each bottle is placed in the machine. Then the machine will grip the bottle gently and flip it to wash thoroughly.

- Equipped with an air-cleaning feature, it will eliminate static and dust particles by using ionized air. This meticulous step ensures that no foreign particles affect the cleanliness of the containers before they proceed to be filled with their intended products.

Following these meticulous cleaning procedures, each bottle undergoes a comprehensive rinsing process for a predetermined duration, guaranteeing that it emerges impeccably clean and ready for filling.

Once cleaned and sanitized, the bottles are seamlessly reintegrated into production by being placed right side up on a conveyor belt, where they await transfer to the filling machine.

This rigorous cleaning process serves as an essential safeguard in preserving food and beverage quality by ensuring that all containers are pristine before any contents are introduced. By upholding stringent hygiene standards through such advanced machinery, manufacturers can confidently deliver safe and flavorful products to consumers around the world.

Types of Air Bottle Rinsers for Versatile Production Requirements

Choosing the right air bottle rinser can make all the difference in your packaging line’s performance and flexibility. Depending on the nature of your products, container shapes, throughput demands, or production space, there are several types of air bottle rinsers that can be integrated seamlessly alongside filling and capping solutions.

Inline Air Bottle Rinsers

Ideal for continuous, high-speed operations, inline rinsers use synchronized conveyors to process bottles in a straight line. These machines are well-suited for facilities managing a steady flow of containers, efficiently handling everything from small-run specialty bottles to high-volume batches. With features like vacuum-assisted dust extraction or diving head technology, they provide reliable cleaning without the bottleneck.

Rotary Air Rinsers

Rotary models excel in high-capacity environments, making them a staple in beverage and pharmaceutical bottling. Their circular arrangement allows for simultaneous rotation and rinsing of multiple bottles, boosting speed and maintaining consistent cleanliness on every cycle. They often use a carousel-like system to maximize output while minimizing floor space.

Gripper-Style Rinsers

If your production line needs to handle bottles or containers that are uniquely shaped—think tapered, square, oval, or heavy-duty plastic and glass—the gripper-style rinser is your go-to. These machines gently secure each bottle, invert them as needed, and thoroughly rinse the interior with ionized air, accommodating a broader range of bottle dimensions and shapes.

Lowerator and Upswing Rinsers

For operations that integrate directly with depalletizers, lowerator and upswing rinsers are engineered to receive bottles from bulk stacks. They invert containers, use ionized or deionized air to blow out particulates, then re-orient bottles for downstream processes. This layout is especially beneficial in large-scale factories leveraging palletized transport and sequencing.

Multi-Station and Indexing Rinsers

Flexibility is key with these systems, which use multiple nozzles—sometimes 8, 12, or even 45+ stations—to process batches of bottles in precise cycles. Indexing conveyors and self-centering neck guides allow for rapid changeovers and consistent results across various bottle sizes, reducing downtime and maximizing throughput.

Other Products Or Services

Whether you’re looking to enhance your existing production line or starting a new project, we have the right solutions for you. Our machines are equipped with advanced features to maintain product quality and minimize waste. Additionally, our knowledgeable team is always available to provide expert guidance and support.