PPackaging products with sachets is an ancient method that is still widely used. Sachet Filling Machine is a more modern method.

Sachets have many advantages: sachets have the basic function of packaging and are the cheapest; they can be used for both transport packaging and sales packaging; they have a wide range of size variations and a variety of materials to choose from, and they are widely adaptable and can be used to pack both solid materials and liquid materials; the gross weight to net weight ratio of sachet products is the smallest, and the space occupied by empty sachets or packages is small; the sachet itself is light in weight, which can reduce freight costs. It can be said that sachet packaging is comparable to any other packaging.

Sachets also have disadvantages: after packaging products, most of them cannot stand upright on the shelf like some rigid and semi-rigid packages; their sealing edges and wrinkles affect the appearance; compared with rigid and semi-rigid container packaging, they have poor strength; and the packaging has a short shelf life.

What Are Sachets?

It is used for sales packaging with a wide range of applications, among which food and daily necessities packaging are the most used, and it can also be used to package small industrial products, such as screws and nuts, electrical components, and small tools.

According to the sachet packaging method, sachets can be classified into prefabricated sachets and sachets for making-filling-sealing machines, completed continuously on a machine with interlaced filling.

Pre-made Sachets

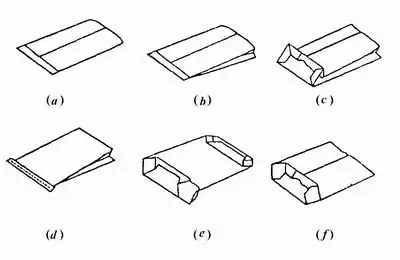

Pre-made sachets are made from paper, plastic and composite materials. Because of the nature of the materials, they differ in form. (1) shows the common forms of paper sachets.

Among them (a) for the flat sachet, suitable for flat products;

(b) the square bottom sachet, can be loaded with thick or more products because of its pleats on both sides;

(c) for the automatic opening of the sachet, as long as you hold the opening of a shake, the mouth of the sachet opens; the bottom of the sachet is a rectangular shape, so it is very convenient to fill;

(d) for the bottom of the sewing of the sachet, you can load the heavier products;

(e) for the bonded sleeve pockets, both ends are sealed in the corner of the sachet end of the bag to install a section of the filling with the tube after filling, the tube will be folded and sealed;

(f) The book bag type sachet has no wrinkles on both sides, which produces convenience. The above six kinds of paper sachets except;

(e) for the open pockets. The mechanism for opening and cutting the paper sachet is serrated. The small paper sachet is opaque, and the barrier is not as good as plastic. Although the price is low, the general production plants are not used. They are mainly in retail stores, in place for customers to package items.

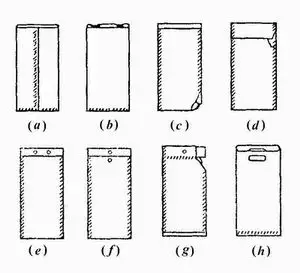

It shows the common form of prefabricated plastic sachets. Which (a) for the back of the lap joint seams of the flat sachet; (b) for the cylindrical film made of both sides of the bag with pleats; (c) for both sides of the seams, the bottom of the bag with pleats. The opening is slightly longer on one side to make it easier to hold open; (d) a bag with seams on both sides and an inwardly extending tongue near the opening, which can be used in lieu of a closure; (e) a bag with seams on both sides and small holes in the opening to allow for hanging; (f) a bag with seams on both sides and tongues and buttons in the opening; (g) a bag with seams on both sides and a reinforcing plate in the opening; and (h) a bag with seams on the bottom and a long, round hole in the opening to allow for easy portability.

The pre-made sachets are made by hand or bag-making machine, and the unqualified ones can be eliminated before use, so the quality is easy to ensure. Specialized bag-making machine to make bags smooth and beautiful, strong seams, and can make shaped bags. However, the pre-made bags are packed with bag filling packaging machine, need to give the bag, open the sachet and other institutions, therefore, low productivity.

Sachet Filling and Sealing

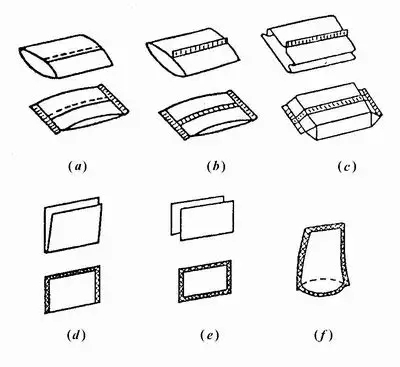

This kind of sachet is with the filling and sealing process is completed continuously on a machine. Made of sachets have the following forms:

(1) pillow-shaped sachet

(2) Three-sided sachet: A roll of packaging material is folded in half and sealed on both sides with the opening.

(3) Upright sachet: made from three pieces of material, one piece is used to seal with the bottom. After filling can be upright, easy to display.

It shows the making and filling packaging machine for the production of sachets. Which (a) for the pillow-type lap seam flat bag; (b) for the pillow-type butt seam flat bag; (c) pillow-type butt seam with side pleats bag; (d) for the three sides of the seal flat bag; (e) for the four sides of the seal flat sachet; (f) for the upright sachet.

Sachet filling and packaging process is reasonably arranged, therefore, saving materials, energy, labor, and high productivity, production costs are also lower, but the disadvantage is that the defects on the sachet can not be found before filling and rejected, can only be inspected after the completion of the packaging, which will result in a certain amount of waste.

How to Fill Sachets?

Load Pre-made sachets and sachet filling methods are different, and the equipment used is also different.

Load Pre-made Sachet

Take out a bag from the sachet storage rack, open the sachet, fill the material, and then seal. Generally in the intermittent very large turn type multi-station sachet filling packaging machine to complete. Due to the more time needed to open the sachet, filling and sealing, low productivity. Filling of solid materials is about half of the package 60 sachets/min, filling of liquid materials can only be packaged 30 ~ 45 sachets/min. Because it is an intermittent movement to increase the speed of certain restrictions, and the requirement to take the sachet accurately, easy to open. Therefore, it is not widely used.

Sachet-making – filling – sealing Machine

The emergence of this sachet method has been nearly 60 years. In the past 20 years, demand for soft sachet packaging has increased with changes in the market, the needs of people’s lifestyles, soft packaging materials, and technological advances. Due to this method of sachets, the process arrangement is reasonable, saving materials, energy, and labor, as well as high productivity and low production costs; therefore, it is widely used. However, there are certain requirements for packaging materials, mostly plastic film and composite materials, with a certain degree of strength.

This sachet method is completed by filling the packaging requirements. There are two types of packaging: the first sachet is the first, and then the sachet is opened separately, filled, and sealed. The other is to make bags, filling and sealing alternately, and complete them continuously. Also known as coherent.