After 2023, Finding reputable,real or leading manufacturers seems to be more easier than before, all these due to the fast development of internet and AI, particularly for specialized and industrial equipment, such as liquid filling machines, involves multiple steps to ensure you receive quality products, reliable service and manufacturer. This comprehensive guide outlines various methods and considerations, offering an in-depth approach to your search, which help you save time and cost.

Comprehensive Guide to Finding Liquid Filling Machine Manufacturers in China

Please note we are guiding you find the manufacturer, not the supplier, find supplier is very easy, but finding a reputation, suitable manufacturer which need special skills.

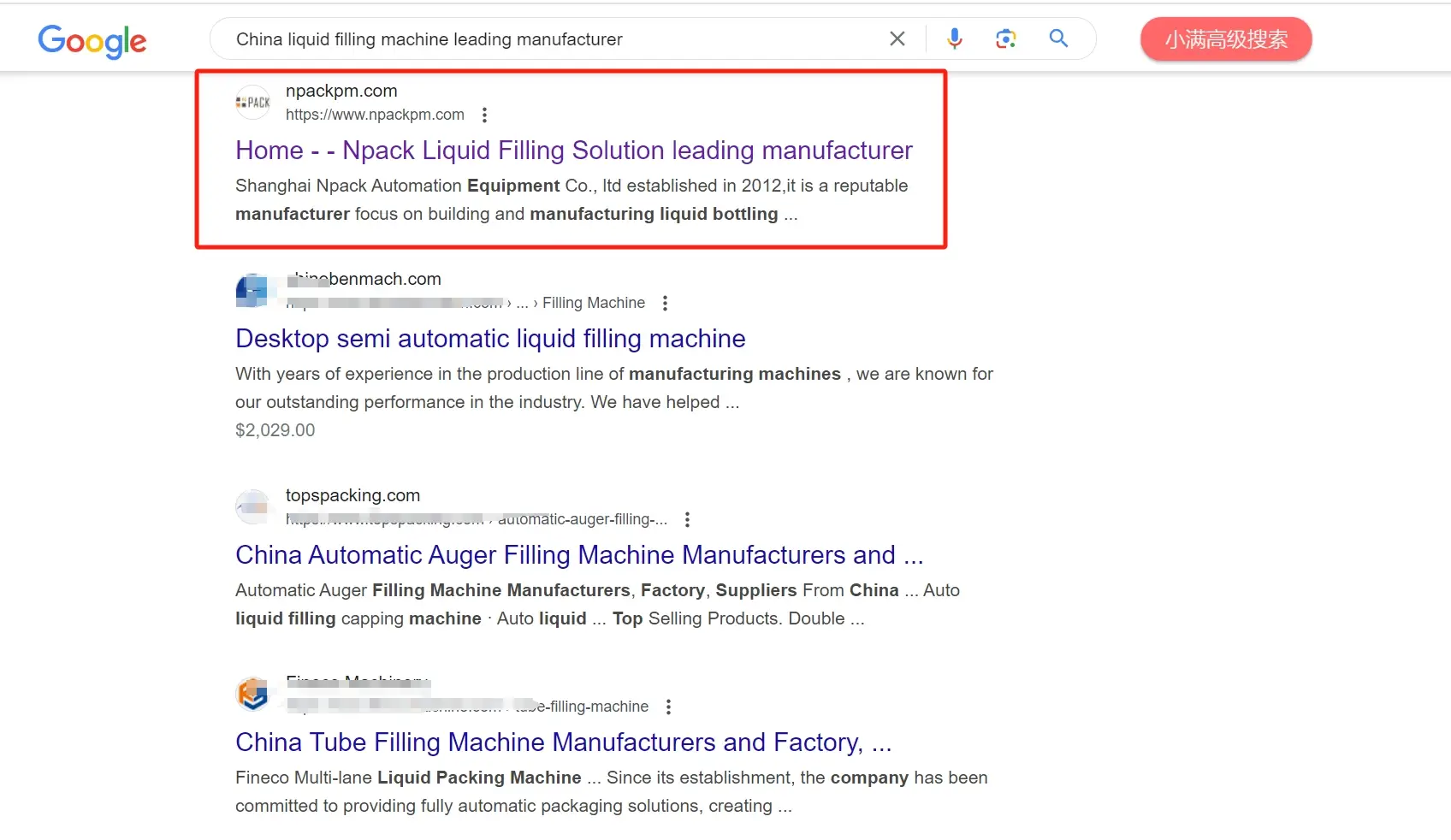

1.Google, bing, yahoo, Yandex or Baidu search engine

The search engine is one of the traditional way to find supplier, but looking for manufacturers, it takes time to Judgment and decide by some terms. ( You can read below how to judgment if it is a manufacturer.)

For example, when we search “China liquid filling machine leading manufacturer”, then search engine will list the supplier to us, the search engine tells us just the one who advertise or SEO top listed one, some of them are manufacturers and some are not. We need to check one by one, but only from their website we can not ensure 100%, but some third party can help us check if it is manufacturer, such as Alibaba, SGS, MADE-IN-CHINA.COM .

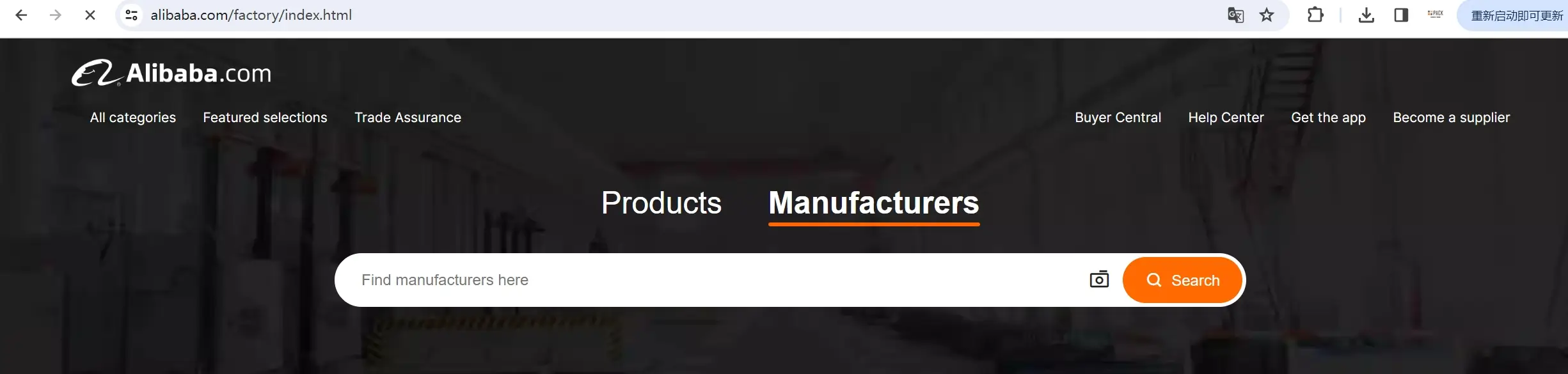

2.Alibaba ,made in china and other B2B marketplaces

Alibaba is one of the largest online marketplaces connecting buyers with suppliers globally, most of the suppliers are from China, some are agent, distributor, trading company and manufacturers.Alibaba offers a vast array of suppliers and has numerous tools to help verify their reliability and check if it is manufacturer.But nowadays alibaba already updated their search box, you can see below image.

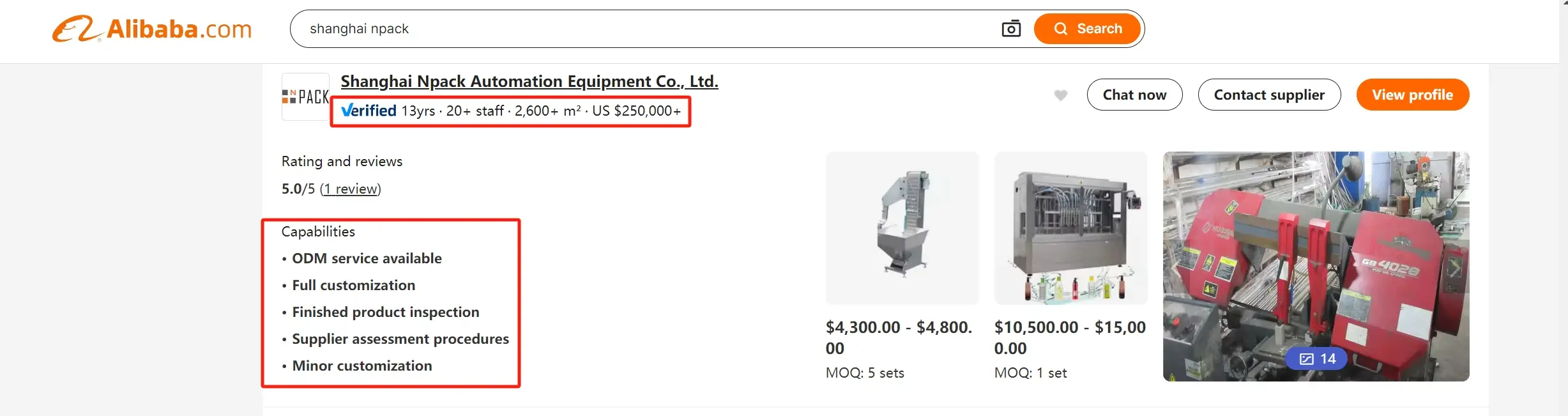

On the image, we can see it has Products or manufacturers as searching option, we can search the manufacturers directly here, but after google searching, we have the “manufacturer” list, we can paste the list name one by one here to check their profile.The alibaba supplier profile is trustable.For example, when we input shanghai npack or npack , we can find the shanghai npack is in the listing, so we can check the profile of the shanghai npack company.

Made-in-China is another prominent platform linking buyers with Chinese suppliers and manufacturers, offering detailed company profiles and product listings. We can find and check the leading manufacturers on alibaba or Made IN china, for 90% of the China suppliers advertise on these 2 plastforms.If you can not find the listed name on alibaba or MIC, so we almost can decide they are not manufacturer.

3.Trade Shows and Exhibitions

Attending a trade shows and exhibitions is a highly effective way to meet suppliers in person, see their products and check the quality, also establish a relationships.But we faced the same issue, not all the exhibitors are manufacturers, so we also can check on alibaba or thirdparty.You can follow npack exhibitions news on our blog to know more about exhibitions news.

4.Industry Associations and Forums

we can find some suppliers and manufacturers list on a industry associations and some industry forums, they also offer the directory list.Joining industry associations and participating in forums can provide valuable connections and recommendations. when we have the list, then we also can check on the same way.

5.AI

the AI tools can tell us the list of the manufacturer, it is the fastest way, when we ask AI, here we take the Chatgpt as an example.When we ask chatgpt, china liquid filling machine manfuacturers , then it will list for us.if we think it is not good enough, and not satisfy, then we can filter the words to Chatgpt. we can specify the products name +leading or top , then it is more accurate.The Chatgpt can list the numbers of the manufactuers according to our order and request,after listing, then we can check one by one.

Steps to Evaluate Manufacturers

1.company or business license,Review the company’s history and track record

2.check on alibaba

3.visiting

Conclusion

Finding reputable manufacturers in China involves a multi-faceted approach. Using online directories, attending trade shows, joining industry associations, conducting thorough research, and seeking referrals are all crucial steps. By carefully evaluating manufacturers’ experience,business license,certifications, product range, and after-sales service, customer listing ,you can make an informed decision and secure a reliable partner for your manufacturing needs.