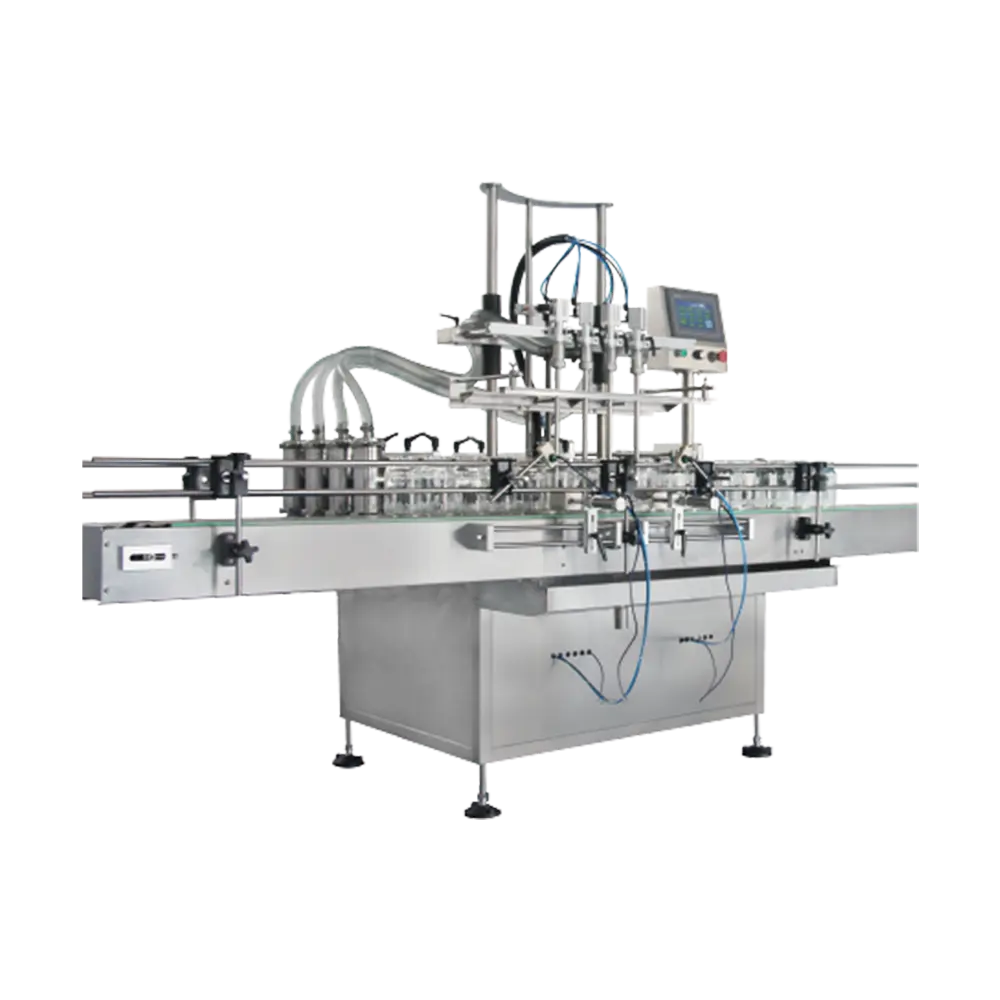

NP-EVF Automatic Horizontal Piston Filling machine

The NP-EVF is an automatic horizontal piston filling machine that driven by a main servo motor or by air cylinder stroke movement and dosing the liquid. As one of the initial designs in automatic piston filling technology, this machine has maintained its popularity for liquid packaging tasks due to its cost-effective and efficient performance, even after several years of advancements in the field.

Constructed from 304 stainless steel, the machine ensures durability and hygiene, with liquid contact parts made of either 304SS or 316SS food-grade stainless steel for added safety. It features a sophisticated “no bottle, no fill” system, managed via PLC controls, and includes automatic alerts for operational failures. The machine is designed with filling nozzles that prevent drips, silk, and automatically cut viscous liquids, ensuring a clean, precise fill every time. The accuracy of the filling volume is within ±0.5%, complemented by a comprehensive bottle counter.

Maintenance is straightforward, requiring no specialized tools. Its horizontal piston cylinder configuration simplifies the disassembly and cleaning process. For handling corrosive liquids, special SKF seals or hoses are utilized to withstand the harsh materials. The machine also offers the option of diving nozzles for bottom-up filling of foaming products, ensuring versatility across a wide range of applications. Additionally, it can accurately locate the bottle mouth for precise filling, and drip trays are included as a standard feature, enhancing the overall cleanliness and efficiency of the filling process.

The NP-EVF stands out for its volumetric dosing capabilities, particularly with semi-viscous liquids and those exhibiting easy flow characteristics. While it comes in its standard configuration without an integrated top liquid hopper or storage tank, this machine uniquely operates by drawing liquid from a proximate tank, thereby dispensing it volumetrically into packaging containers through a horizontally aligned piston cylinder. This method ensures precise volume control and consistent product dispensing. Importantly, the NP-EVF is most effectively applied in industries requiring accurate volume filling for products not characterized by high viscosity. Its application fields span a wide range of sectors, from food and beverages to pharmaceuticals and cosmetics, making it a versatile choice for businesses seeking efficient and accurate liquid packaging solutions.

| 1 | Model | NP-EVF |

| 2 | Operational mode | Automatic |

| 3 | Product applications | For liquid and viscous liquid |

| 4 | Filling range | 100-1000ml or 500ml to 5000ml |

| 5 | Number of heads | 2 or 4 heads |

| 6 | Filling Capacity | 500b/h to 1200b/h base on 1000Ml viscous liquid |

| 7 | Measurement precision | ±0.5% base on 1000ml |

| 8 | Working power | 220VAC single phase |

| 9 | Air pressure | 6~8㎏/㎝² |

| 10 | Air consumption | 1m³/min |

| 11 | Power rate | 0.8kw to 1.5KW |

| 12 | Other devices power rate | 7.5kw(air compressor) |

| 13 | Net weight | 320Kg |

- vacuum filling nozzles

- the filling nozzle is driven by a servo motor to move up and down

- the specially designed shut off filling nozzles.

- For some highly corrosive liquid products, this machine can adapt PTFE pump, PTFE hose and sealing material, so as to avoid the corrosive of the machine

- Each servo motor driven by each piston stroke movement individually

- Mixing top hoppers

- Double jacket hopper with heating

- Pressure top tank

- Rotary valve for food sauce with granular solid

.